Global Leader in Plant Cell Fermentation (PCF®)

Phyton Biotech develops and applies sustainable and “green” chemistry manufacturing solutions for phytochemicals using PCF®, serving the Pharmaceutical, Traditional Chinese Medicine (TCM), Cosmetic, Agricultural and Food Ingredient industries.

Utilizing our revolutionary PCF® platform, Phyton offers a time, risk, and cost-balanced path to commercially viable production processes. With certified GMP facilities in Germany and Canada, Phyton combines highly developed technology and quality to meet our global customers’ needs. We have a successful track record of developing and implementing innovative contract development solutions for clients around the world.

What is Plant Cell Fermentation (PCF®)?

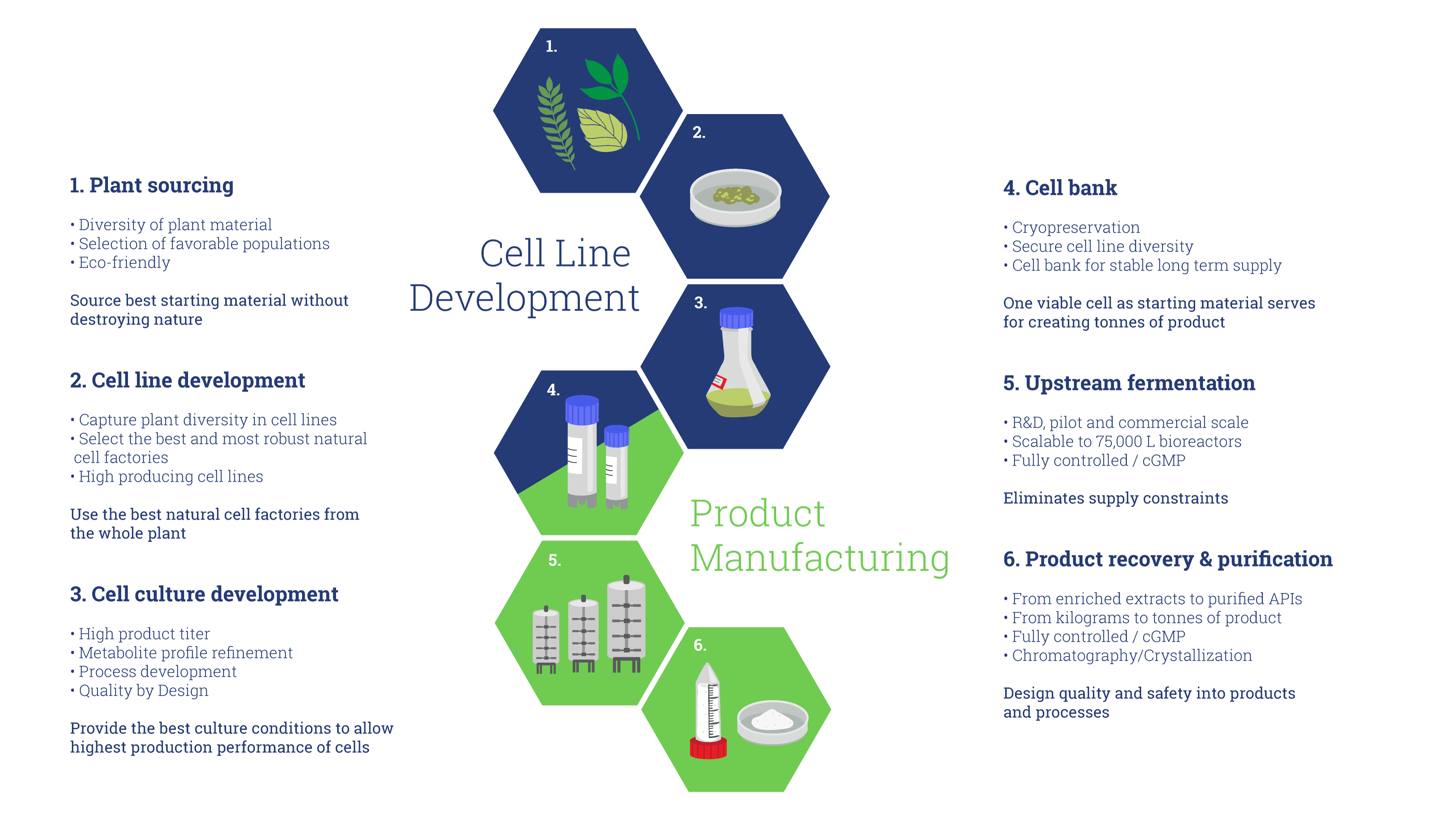

Plant Cell Fermentation (PCF®) Technology promotes the natural processes of plant cell growth and biosynthetic pathway expression ex planta in a controlled and fully defined fermentation environment:

- Non-GMO viable plant cell suspensions are used

- Starting material comes from cryopreserved cell bank

- Medium is fully defined, protein-free and does not contain animal-derived components

- Process is operated in aerated stirred tanks with proven scale-up technology

- Fermentation product can be simply extracted or further processed to concentrated active ingredient, such as for production of paclitaxel

- Fully controlled or even GMP compliant environment

Why Plant Cell Fermentation (PCF®)?

PCF® provides many advantages over traditional methods of developing and producing phytochemicals.

Applications of Plant Cell Fermentation (PCF®)

- Supply solutions for plant-based molecules in multiple industries

- High-quality Active Pharmaceutical Ingredients (APIs) and precursors thereof

- Innovative Active Cosmetic Principles

- High-value ingredients for the flavour & fragrance industries and other food and health applications

- Safe, reliable and cost-effective way to produce high-value recombinant therapeutic proteins

Producing Phytochemicals with Plant Cell Fermentation

Custom Process Development

Our team of experts at Phyton Germany can develop new processes for clients for a variety of complex plant-based molecules. Based on our significant experience working with phytochemicals using our award-winning (PCF®) platform, Phyton is capable of developing custom processes to meet the needs of clients across the Pharmaceutical, Traditional Chinese Medicine (TCM), Cosmetic, Agricultural and Food Ingredient industries.